THE CHALLENGE

A manufacturing plant required a welding process that delivers consistently at high quality

Cost of Labor

Manual welding requires high level of skill and time, increasing the cost of direct labor

Human Factor

Any human process requires an iterative monitoring and check for defects & pin holes

Productivity

Human fatigue, accidents or absentees all result in the loss of productivity

Transformation Strategy

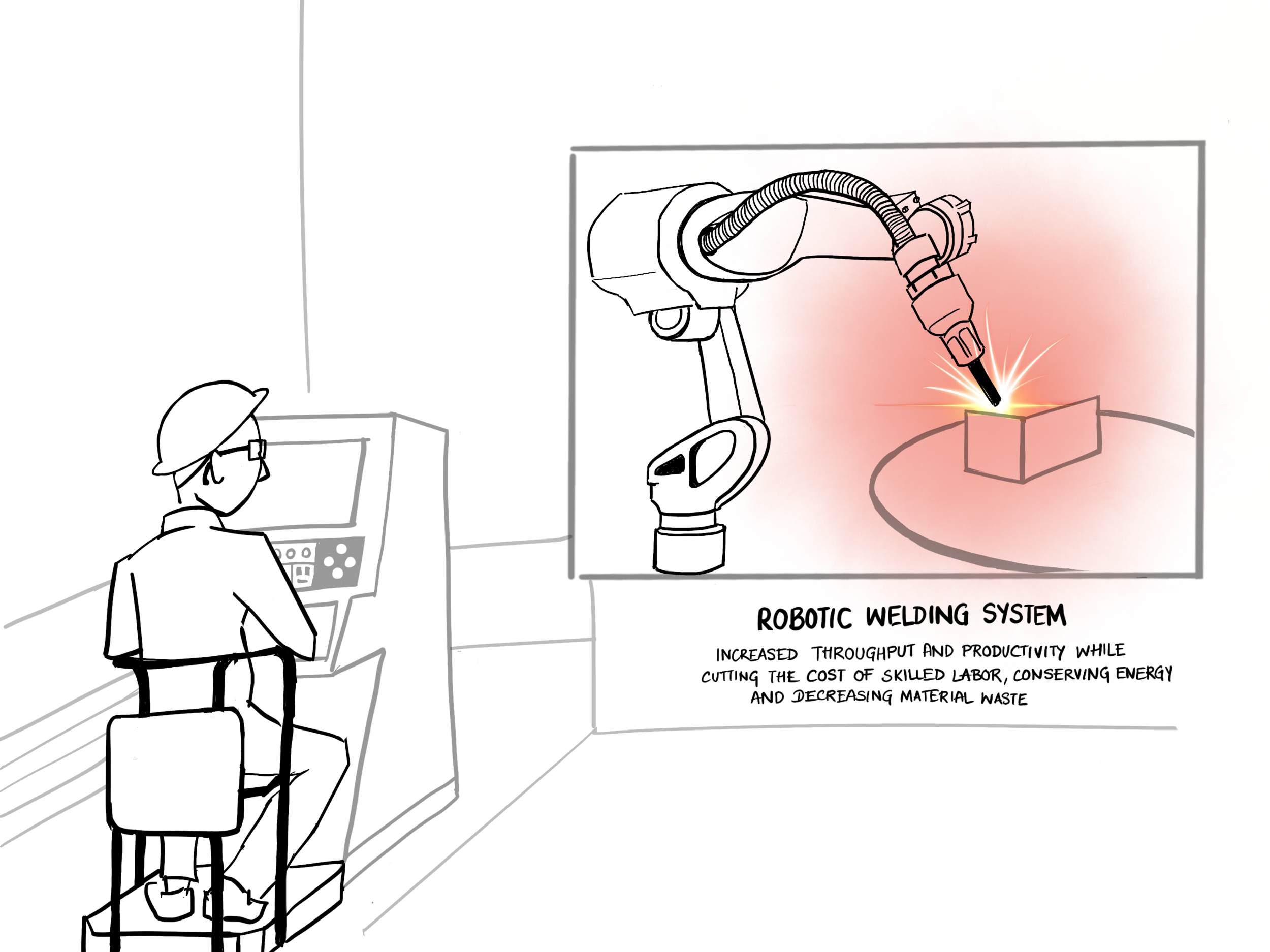

Robotic welding system

An automated process working without interruption increasing productivity while conserving energy by regulating power

Improved Accessibility

Robot arms can rotate 360 degrees and have a 3 axis movement allowing access to all portions of the workpiece

Single man operation

Robot operators can be easily trained to get familiar with the welding functions

Solution Impact

Reduces cost of skilled labor

Increases reliability in quality

Increases throughput